We can take on your toughest challenges.

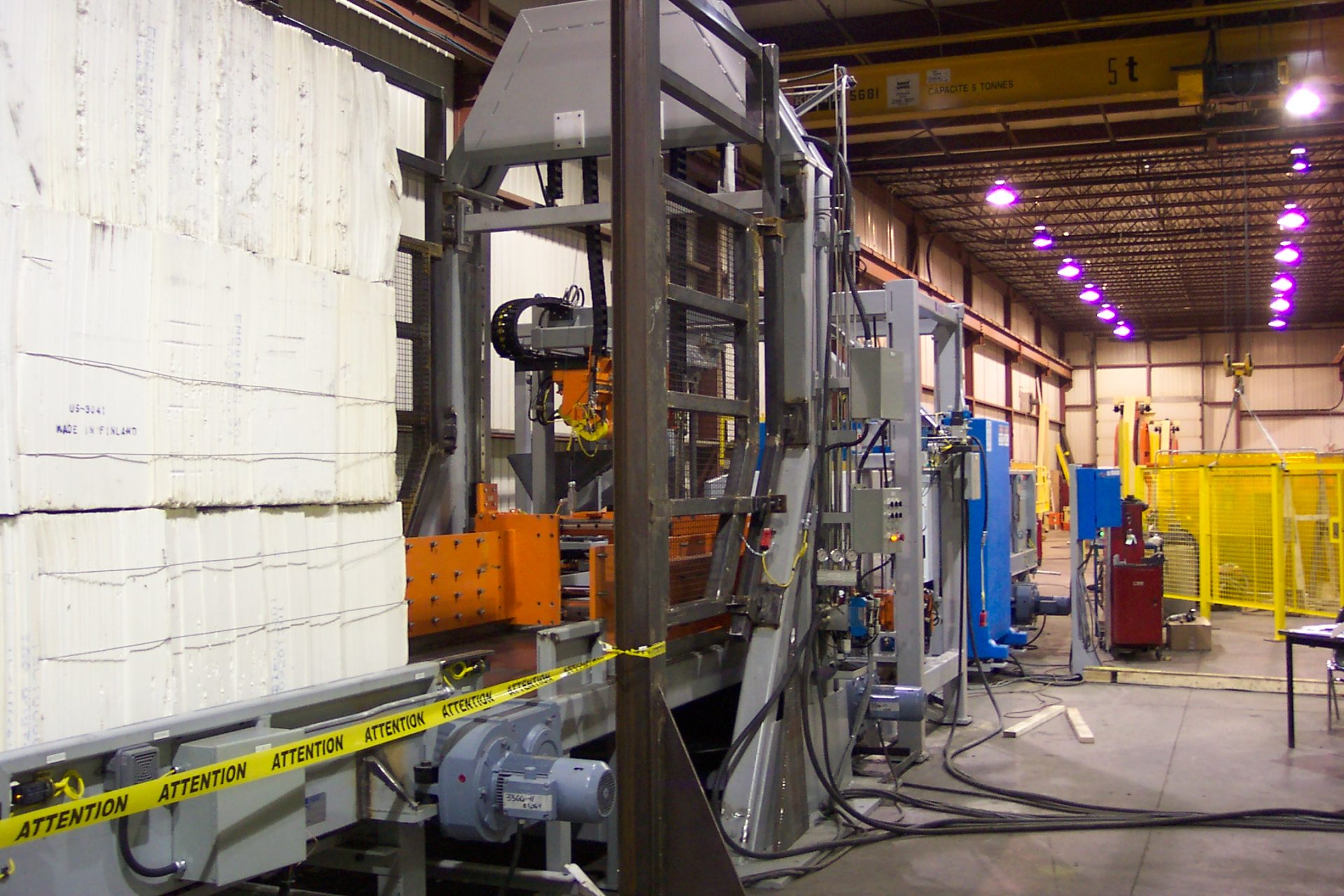

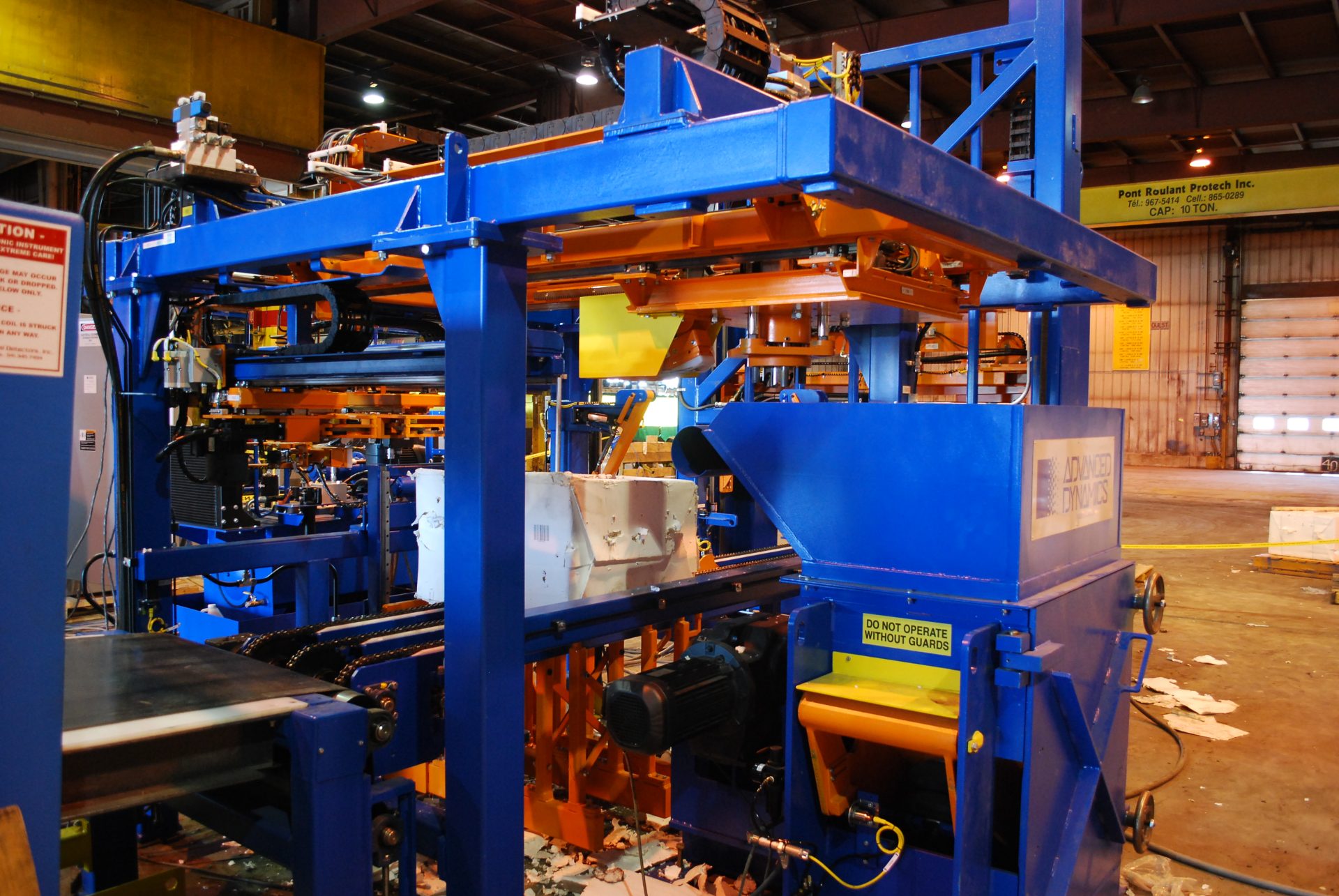

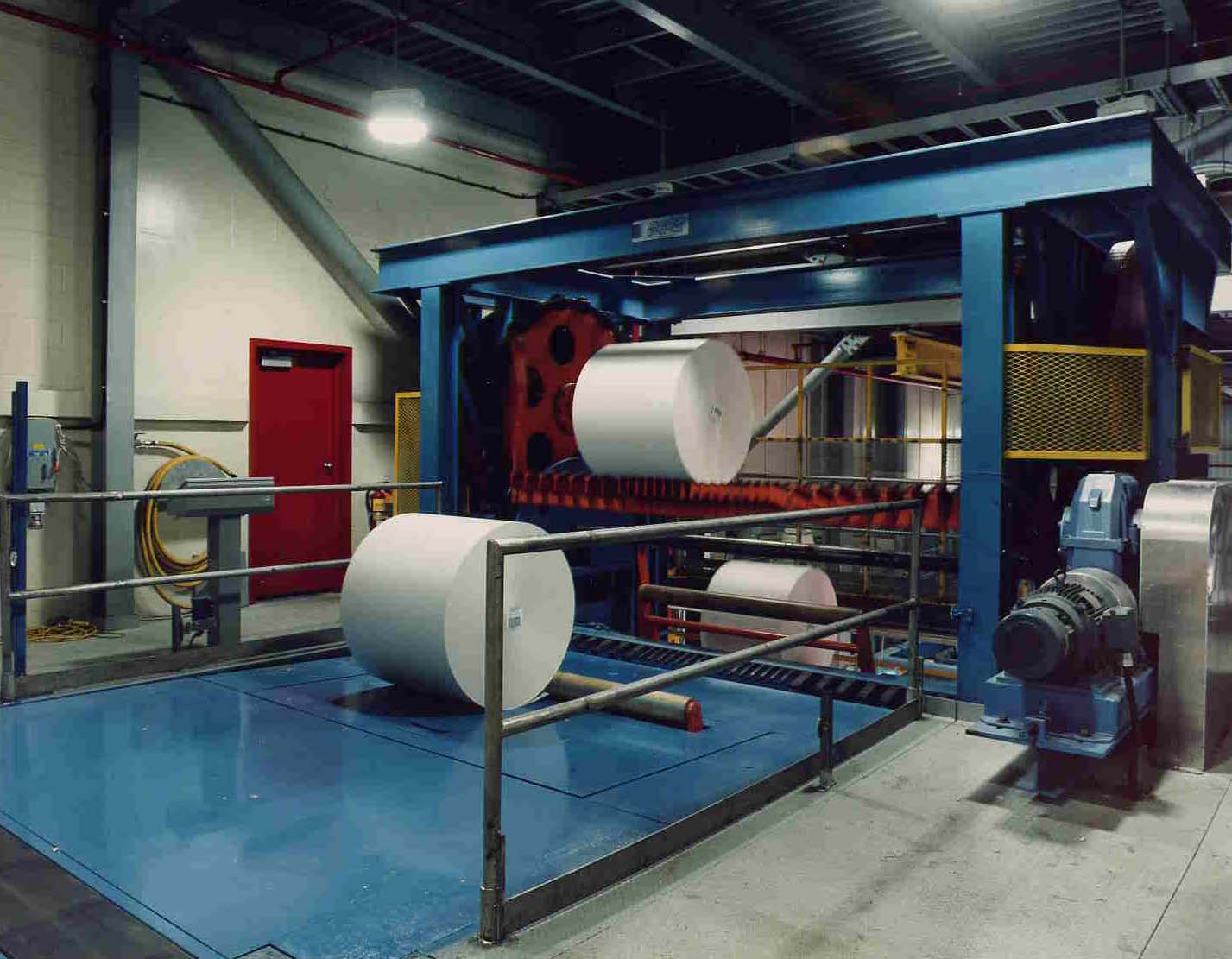

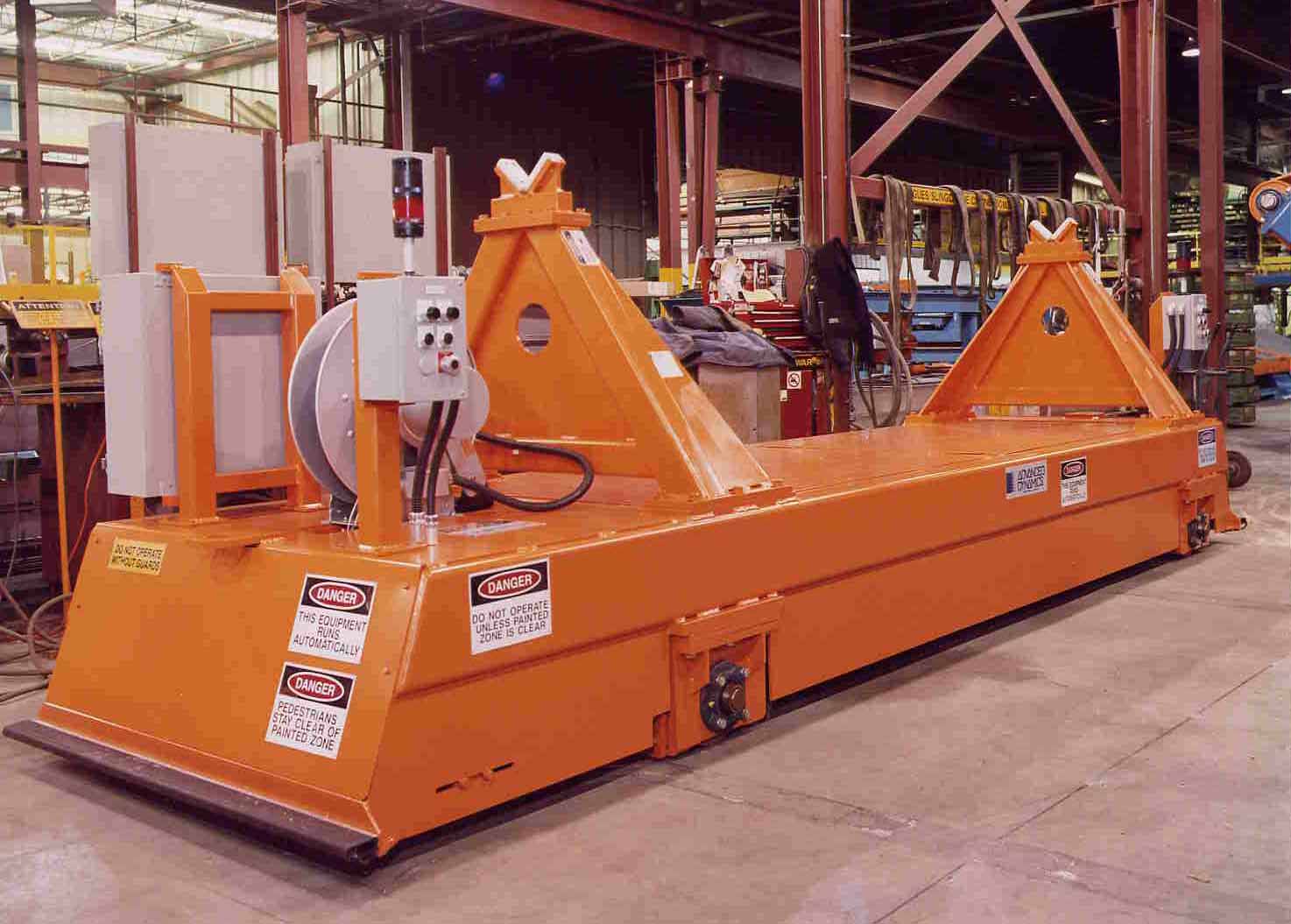

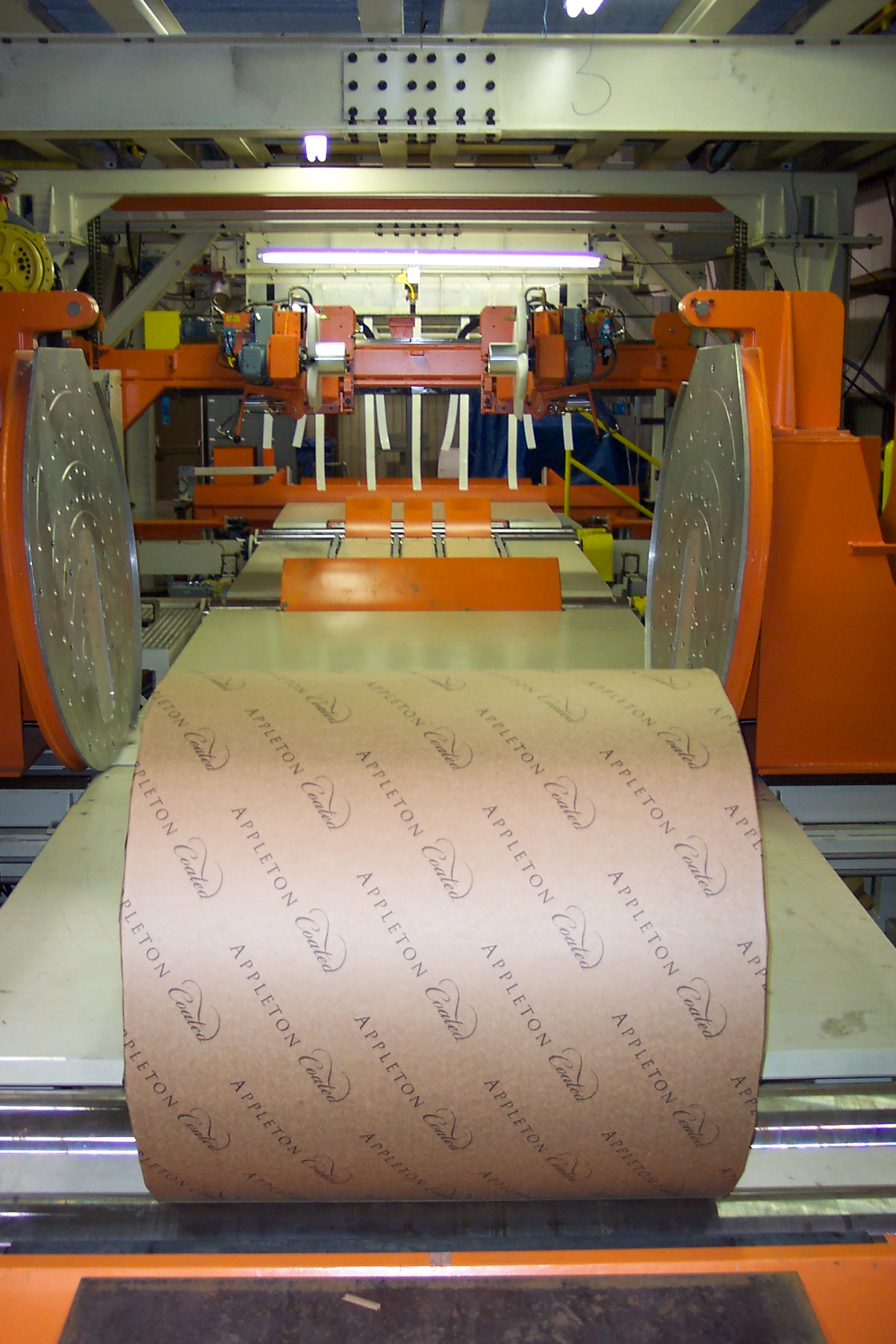

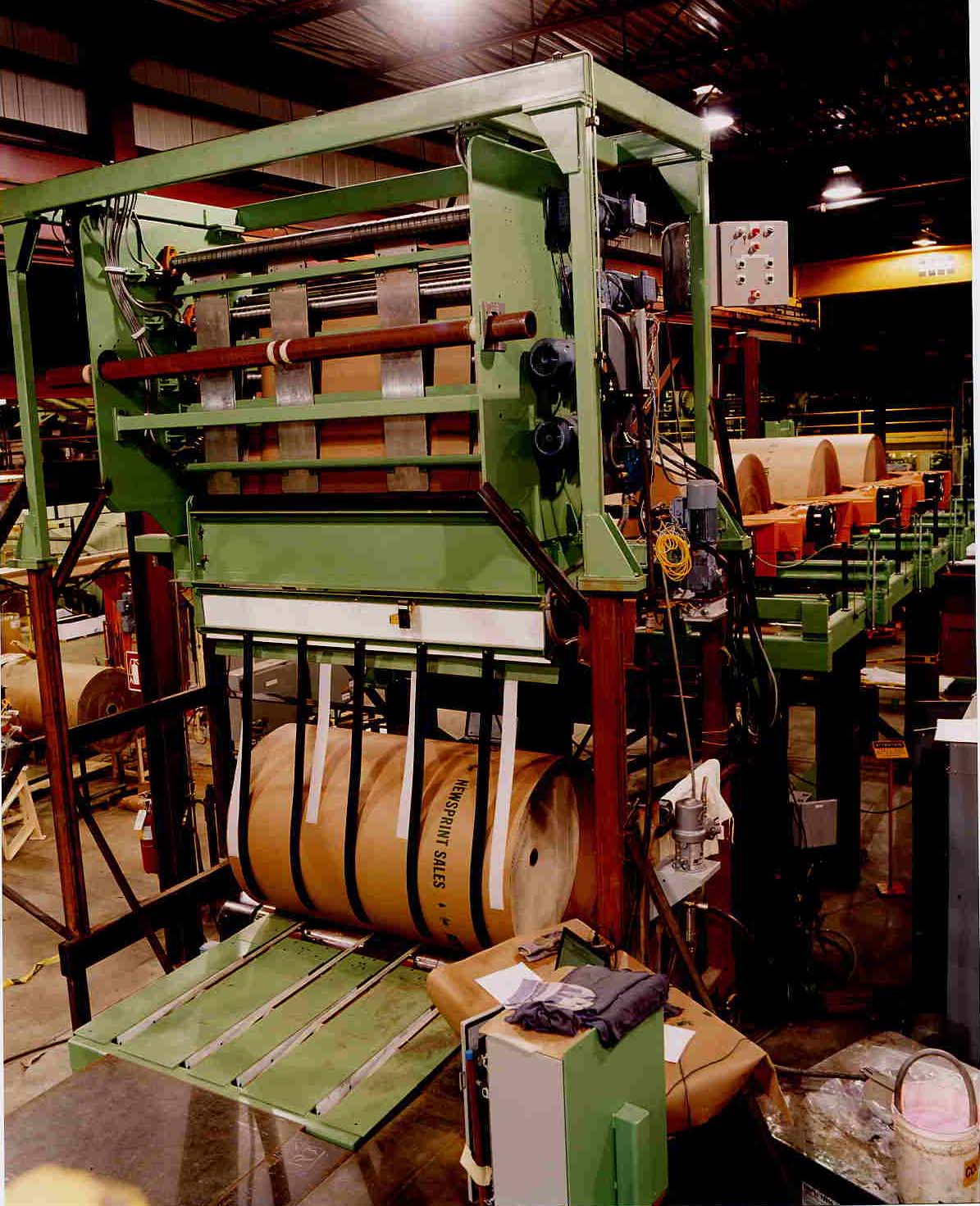

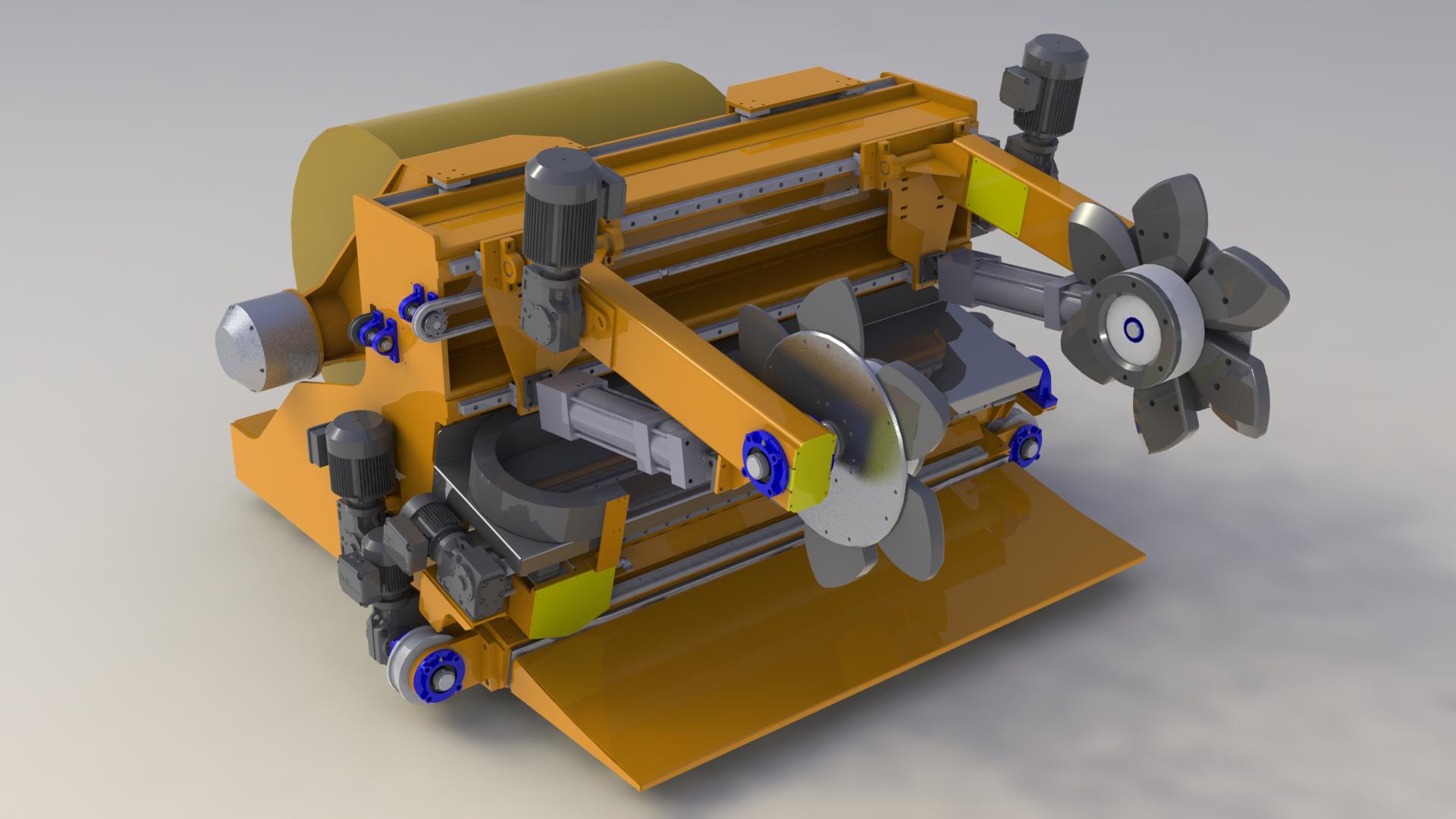

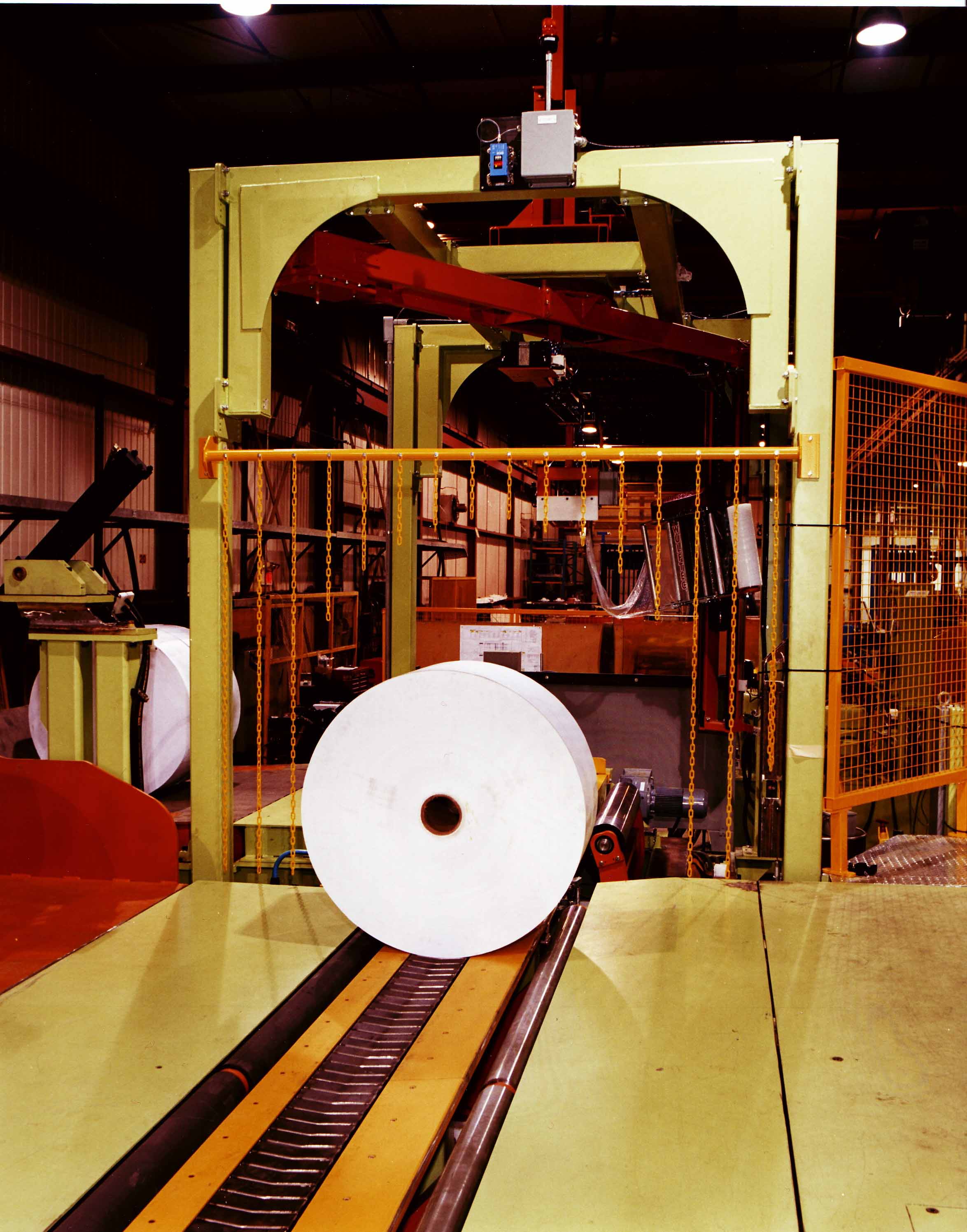

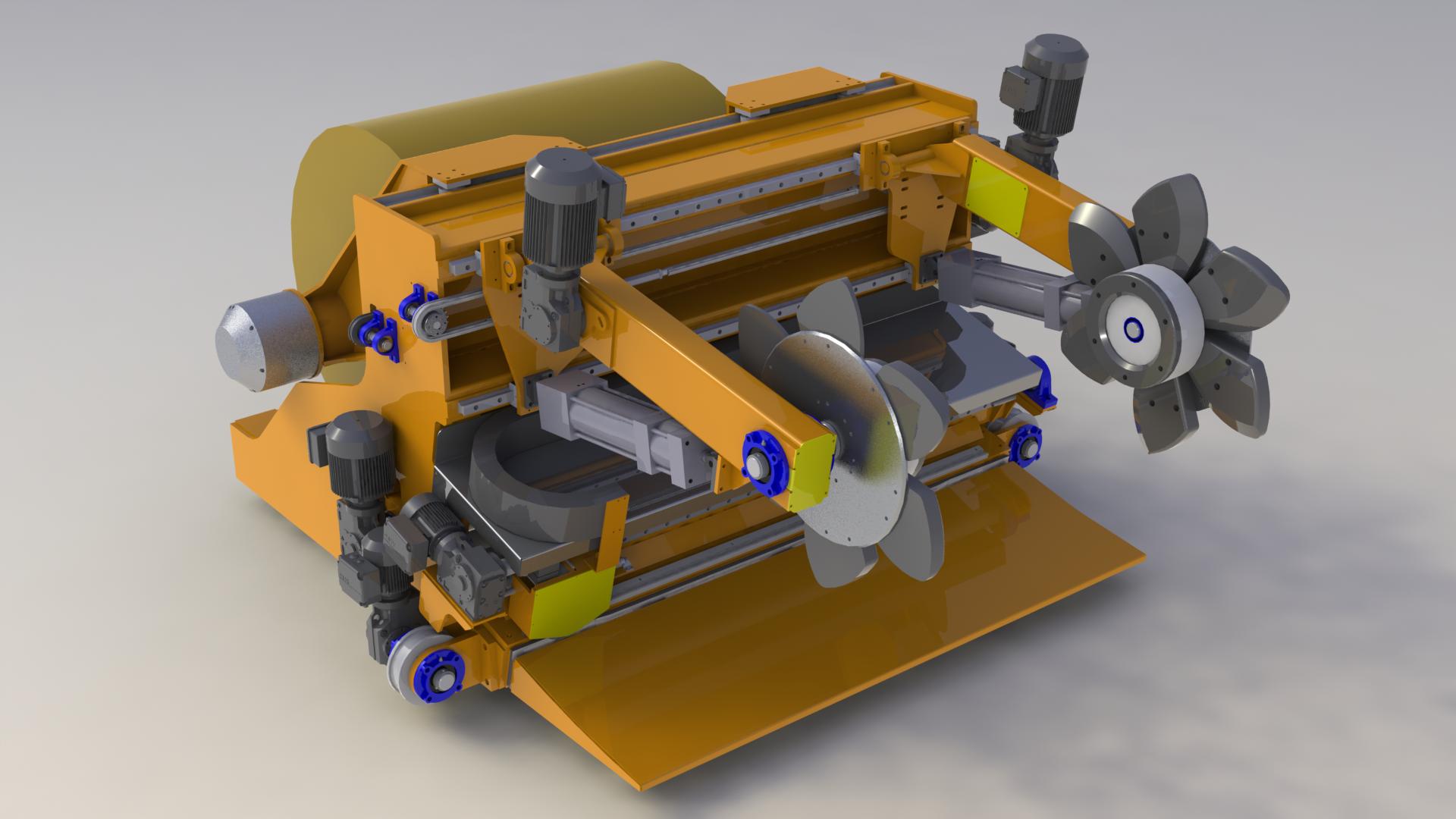

End-to-end handling solutions.

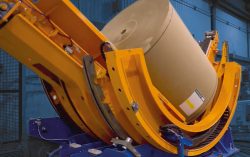

From the pulper infeed, the winder deck to the warehouse.

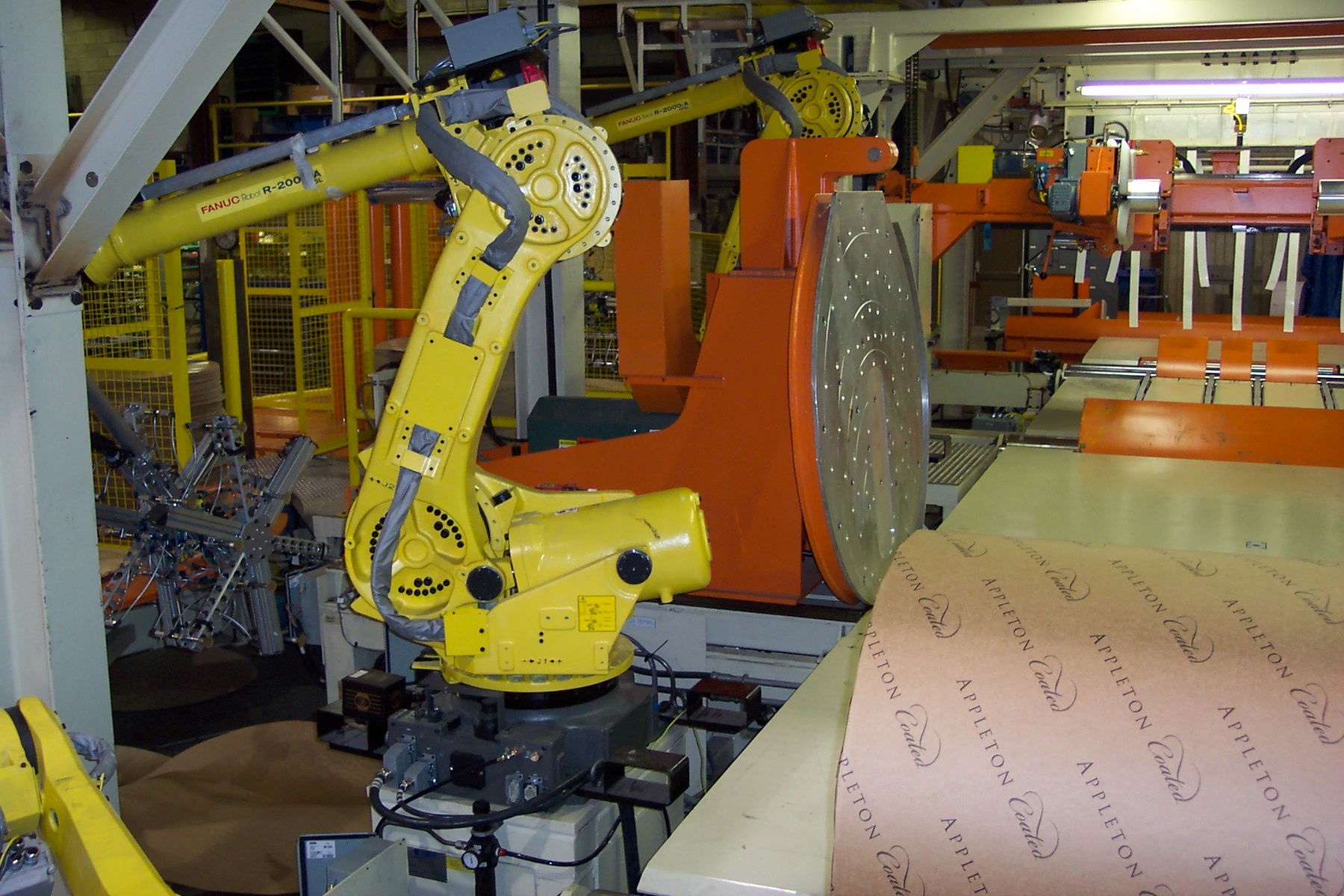

We offer automated equipment solutions for handling and operations.

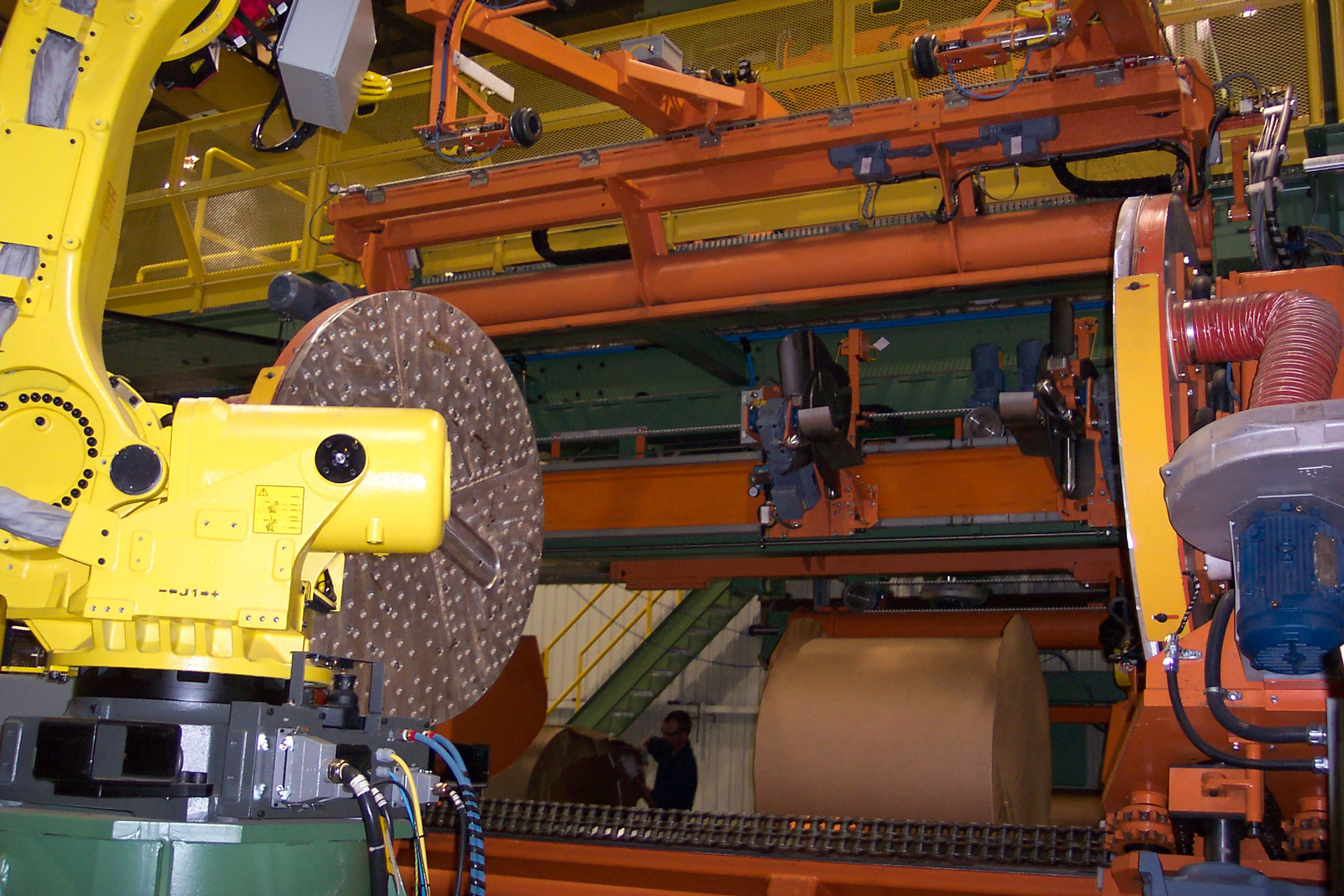

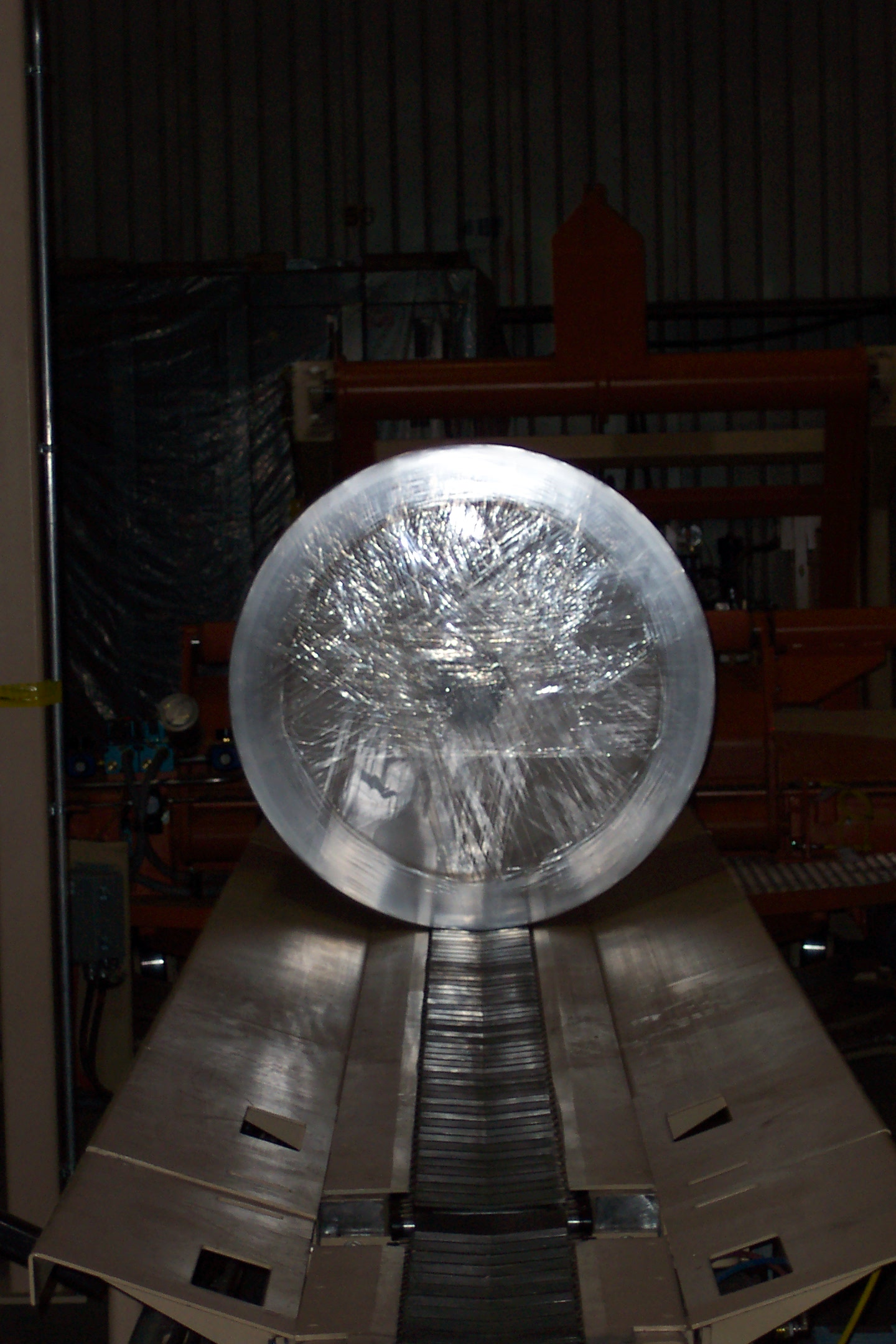

Wire removal is our specialty, see our latest line of robotic dewirers.

Watch our video showing EPIQ global solutions for the Pulp & Paper industry.

EPIQ Machinery is your partner in improving your productivity in your paper mill. Our group of highly trained engineers, designers and project managers will help you get the most of your plant on time and within your budget.

We can take on your toughest challenges. Our goal? Increase your productivity. 5 decades of successful business speak for themselves.

We take pride in developing new equipment or an overall material handling solution for your specific pulp and paper mill requirement. Contact us today!